The KAHL (Course of) Expertise: Over 30 years of success

Along with the flat die pellet mill, with which AMANDUS KAHL has made a reputation for itself on the worldwide financial market in varied industries for a number of many years, the expander can also be a part of the product vary of the German machine producer. With regard to feed manufacturing, the KAHL annular hole expander and the expander know-how are among the many finest and only conditioning processes for compound feed and particular person parts.

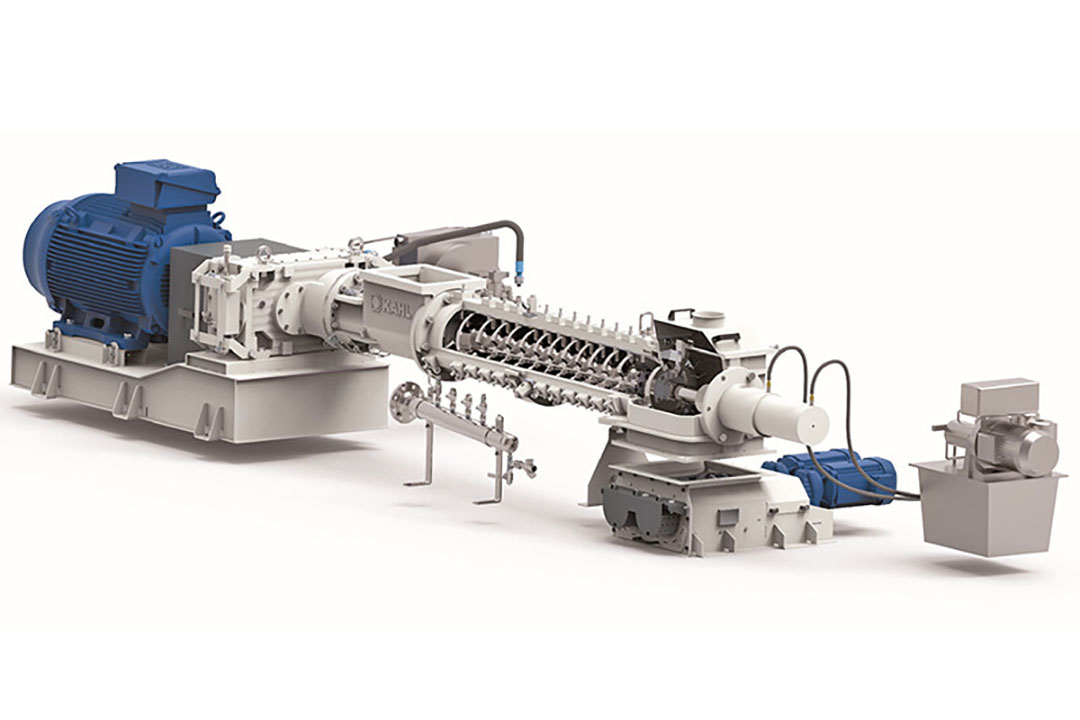

The KAHL expander is pushed vitality effectively by a gear with built-in predominant bearing and consists of a thick-walled, wear-protected tube – geared up with wear-resistant proportioning, mixing and kneading components. In contrast to the extruder, which is supplied with a die at its entrance finish, the expander finish is supplied with a hydraulically adjustable cone which varieties an annular hole with the fastened outlet ring. Via adjusting the cone throughout operation, stress, depth of kneading, product heating and vitality consumption could be managed and programmed repeatedly and instantaneously. Relying on the product, the stress is between 5 and 120 bar, the working temperatures on the expander outlet are between 90 and 120°C to 130°C for many purposes, relying on animal species and feed, however can be increased for extra particular purposes. The conditioned product is discharged from the KAHL expander by way of the cone. The stress drops, the product expands and a part of the added water evaporates (flash evaporation). Submit-drying is normally not mandatory. The particle dimension of the expanded product could be decided via the downstream crushing system.

Comments

0 comments